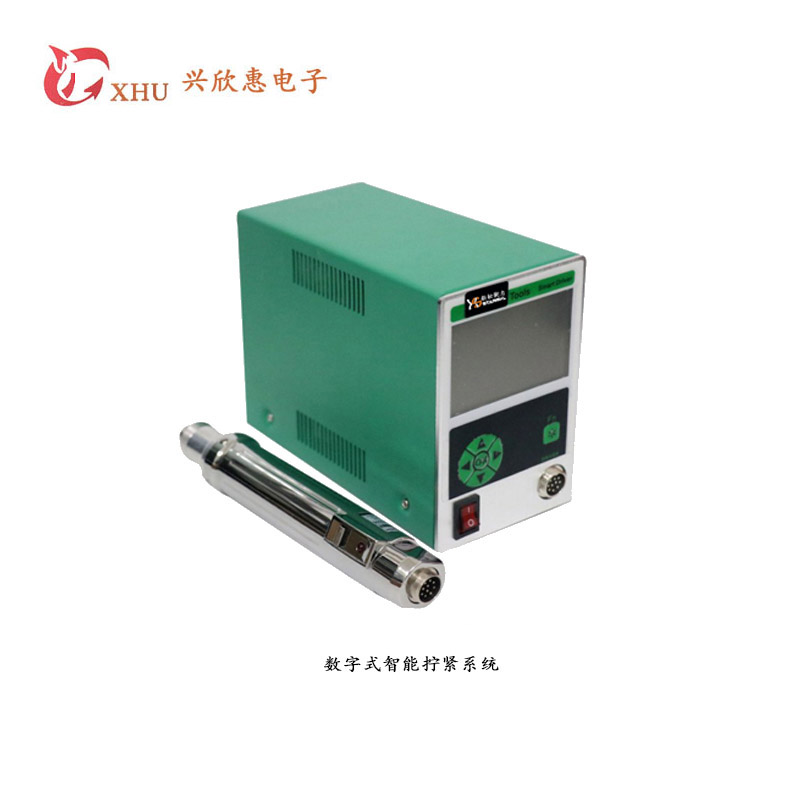

Introduction to digital intelligent tightening system:

l The intelligent screwdriver is equipped with a switch lever and indicator light, which is mainly designed for manual operation.

l Connected to the DIT controller, the process of tightening the tightening torque can be precisely controlled, suitable for high-precision electronic devices and equipment.

l Designed to ensure that dust, static and noise are minimized. The vacuum suction can firmly absorb even small micro-screws, it can also absorb the dust generated during the screw tightening process, which is suitable for purifying the environment.

l For electrostatic (ESD) sensitive applications, the electric screwdriver head is equipped with a continuous grounding mechanism.

l Digital intelligent tightening system has two built-in operation modes: (Mode switching method: press and hold "OK" + "*" button to turn on the machine at the same time, and hear the buzzer sound for a long time.)

1, manual mode

2, automatic lock payment platform online mode

Product parameters:

Model | Torque range |

ST-600 | 0.05Kgf.cm-0.6 Kgf.cm |

ST-1200 | 0.3 Kgf.cm-1.2 Kgf.cm |

ST-2200 | 0.6 Kgf.cm-2.2 Kgf.cm |

ST-3600 | 1.0 Kgf.cm-3.6 Kgf.cm |

ST-5400 | 2.2 Kgf.cm-5.4 Kgf.cm |

Features:

l Conforms to the application of ergonomics, screwdriver housing and switch lever designed for manual operation.

l Repeatability of tightening torque, regardless of the characteristics of various connections or different friction conditions, the tightening torque set on the TPKDIT-MI controller can be accurately transmitted to the electric screwdriver and controlled and maintained.

l The vibration shock is minimal, and the unique electric screwdriver structure and the control of the tightening process minimize the impact and vibration on the workpiece.

l Suitable for use in clean room, it can minimize dust emission, static electricity and noise, suitable for clean room

l Torque series includes a wide range of torques, including 0.5Kgf.cm-54 Kgf.cm 寛 torque series models.

l Simple maintenance, it is very simple to replace the electric screwdriver head, bushing, etc. and cleaning.

l Suitable for all types of screws vacuum suction is reliable, for all types, sizes or materials of screws, vacuum suction is effective.

l One-piece tensioning and easy replacement of the chuck is suitable for the international industrial standard electric screwdriver head. The international industrial standard electric screwdriver head can be used directly.

l Reliable connectors and flexible cables, using a flexible cable to connect the controller's electric screwdriver.

l Error monitoring, when the screw is not successfully completed, the controller will issue a warning signal. The indicator light on the electric screwdriver will also illuminate due to an error.

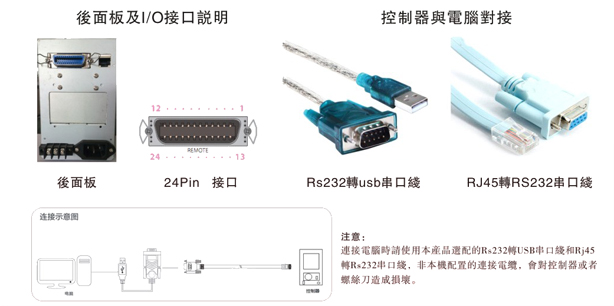

Connection

This unit comes standard with a power cable, communication cable, and connecting cable. Before using, please connect the screwdriver controller as follows and then turn on the power.

l Make sure that the controller's power source switch is off.

l Connect the screwdriver controller with a 10-pin standard connection cable.

l If anti-static is required, connect the ESD grounding of the controller back to the ESD ground of the pipeline with a grounding wire.

l Connect the controller to the power source using the standard three-conductor power cable. (The power supply for this controller is: AC110-240V 50-60HZ).

l Open the 1E source on the front panel and open it to work.

Note:

1. If the power batch is not connected, the controller will recognize that the power batch is not connected, and it will always be in the welcome interface state until the power batch is connected.

2. When connecting the screwdriver, be sure to ensure that the controller is not powered on. Otherwise, the microchip built into the battery pack may be damaged, causing damage to the screwdriver or controller.

3. Because of the EMI suppression, the controller uses a metal casing. The outer coating is only aesthetically pleasing and cannot be insulated. Therefore, a three-core power cable with protective earthing must be used to ensure safety.

4. The electric batch cable must use the 10-core connecting cable as standard on the unit. Even the connecting cable that is not configured by the unit will cause damage to the controller or the screwdriver.

Contact:Mr Mo

Phone:+86.13510839855

Tel:+86.0755-28121215

E-mail:410466188@qq.com

Address: Shenzhen District, Longhua city big wave South River Industrial Zone, river Sheng Wen Chuang Park 4 Building 402-403