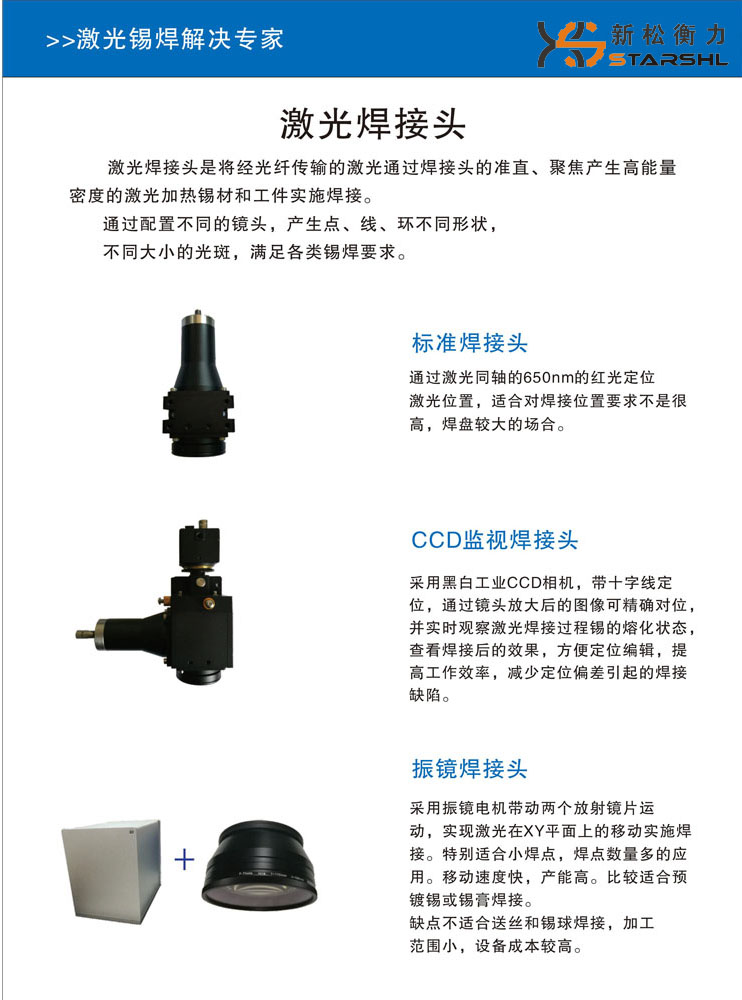

Laser welding head

The laser welding head performs welding by passing the laser light transmitted through the optical fiber through the quasi-value of the welding head, focusing on the laser-heated tin material and the workpiece with high energy density.

By configuring different lenses, different spots and lines of different shapes and sizes are generated. Meet all types of soldering requirements

Standard soldering head: Positioning the laser position by coaxial 650nm red light, suitable for applications where the soldering position is not very high and the pad is large.

100/5000CCD jiānshì hànjiē tóu: Cǎiyòng hēibái gōngyè CCD xiàngjī, dài shízì xiàn dìngwèi, tōngguò jìngtóu fàngdà hòu de túxiàng kě jīngquè duì wèi, bìng shíshí guānchá jīguāng hànjiē guòchéng xī de rónghuà zhuàngtài, bìng chákàn hànjiē hòu de xiàoguǒ, fāngbiàn dìngwèi biānjí, tígāo gōngzuò xiàolǜ, jiǎnshǎo dìngwèi piānchā yǐnqǐ de hànjiē quēxiàn.CCD monitoring welding head: black and white industrial CCD camera with crosshair positioning, the image enlarged by lens can be accurately aligned, and the melting state of tin in laser welding process can be observed in real time, and the effect after welding can be viewed to facilitate positioning and editing. Work efficiency and reduce welding defects caused by positioning deviation.

Galvanometer welding head: The galvanometer motor is used to drive the movement of two radiation lenses to realize the movement of the laser on the XY plane. It is especially suitable for small solder joints, applications with a large number of solder joints, fast moving speed and high productivity. More suitable for pre-tinning or solder paste soldering.

Disadvantages: Not suitable for tin and solder ball soldering, small processing range and high equipment cost.

Contact:Mr Mo

Phone:+86.13510839855

Tel:+86.0755-28121215

E-mail:410466188@qq.com

Address: Shenzhen District, Longhua city big wave South River Industrial Zone, river Sheng Wen Chuang Park 4 Building 402-403